Slippers are a kind of shoes, followed by a full-empty, only the front of the toe, mostly flat, the material is often quite soft leather, plastic, cloth and so on. The types of slippers are differentiated according to the occasion of wearing and performance. For example, beach slippers, not plastic fabrics, but plastic, this is for waterproof, good cleaning, the shape of the toe is also specially designed, often referred to as flip-flops, which is what we call flip-flops. However, indoor slippers in winter are used to keep warm and may use fluffy cloth instead of plastic, so that people can enjoy better in the living room. There are also anti-static slippers commonly used in electronics factories and dust-free factories.

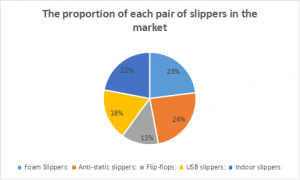

First of all, first understand the share of various types of slippers in the market.

Today, I mainly talk about the processing of plastic slippers.

Performance comparison of commonly used plastic products

TPR bottom: soft, waterproof, with a certain degree of wear resistance, touched is the rubber feel that everyone is familiar with, and one is based on the TPR, pressed into the cloth, increasing the durability of the TPR.

EVA bottom: firm, lightweight, easy to clean, comfortable, breathable, soft, rich in color. Easy to process, easy to bond, not easy to fall off. Suitable for beach sandals, home casual sandals, travel slippers, etc.

PVC bottom: PVC bottom is also mostly used in Japanese and Korean slippers. Probably because most of the Japanese and Korean families are wooden floors and carpets, the bottom slippers are basically the same, so it is convenient to wear and replace. Therefore, this kind of bottom is most popular in Japan and South Korea, it will not be contaminated with dust, and it will be dirty if it is wiped off on the cloth. However, it is not very acceptable for the Chinese, because its foot feel is relatively blunt.

Plastic bottom: This kind of bottom slip is very good because its mute effect is also used in many high-end hotels and hospitals, soft, lightweight and non-slip.

Plastic slippers production process

1. Ingredient kneading: Pour the raw material PVC resin into a human kneading machine, and then add various additives to perform heating and kneading. The heating steam pressure is about 0.29 MPa, and the dough is discharged after 45-60 minutes.

2. Plastic pull-tab: The kneaded mixture is sent to a two-roller plastic mixer for plasticating and pulling, and the mastication temperature is controlled at about 130 °C.

3. Mold pressing: The sheet which is pulled after the mastication is pressed into a piece of the sample (generally rectangular), and the pieces of various colors can be matched according to the color of the sole, and then the piece is weighed according to the cavity capacity. The material, weighing should be more accurate to prevent flash or lack of material. Subsequently, the mold containing the sheet material is sent to a hot press for heating plasticizing, foaming, foaming, cooling and setting, and then demolding to remove the plasticized billet. The process conditions for molding the crucible are: molding plasticizing temperature of 160-165 ° C. The heating steam pressure is 0.686-0.784 MPa, the molding plasticizing pressure is 4.9 MPa, the molding plasticizing time is 10-20 min, the cooling setting temperature is 50 ° C, and the cooling setting time is 20 min.

4. Heat treatment: The purpose of the heat treatment is to further heat and foam the billet under normal pressure to obtain a foamed sole sheet. The operation is to feed the billet into a steam-heated drying room, and control the temperature at 100-130 ° C. 10-15min, make it foam, the foamed sheet of the obtained foaming slippers bottom out of the drying room, and then sent to the library for a week, and then can be sent to the punching.

5. Blanking and assembly: The foamed sheet material is punched into the slippers according to the specifications of the slippers, and then the eyes are punched and assembled with the slippers to obtain the finished slippers.

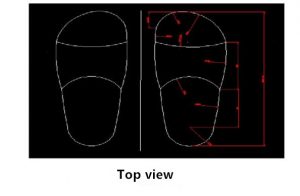

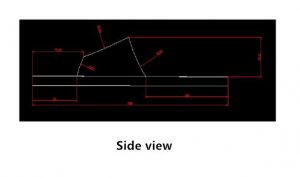

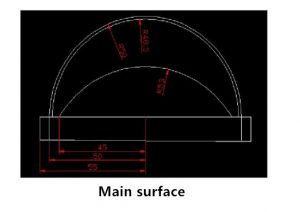

Plastic slipper structure pattern

If you want to customize your slippers, check out our custom blog or custom service.